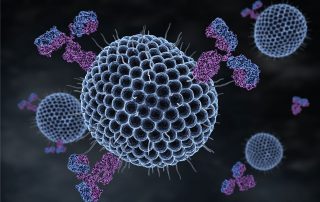

Different Types of Viral Vectors for Gene Delivery and How They Are Used

Viruses are appealing vectors for gene delivery because they have evolved over time to deliver nucleic acid directly to specific cells. The same traits that make viruses difficult to treat—their efficiency at targeting particular cells and their ability to avoid immunosurveillance—make them excellent candidates for gene delivery in both research [...]

What Can We Learn from Non-Touch Techniques for Aseptic Manufacturing?

Many people who work in the field of aseptic manufacturing may never have heard of aseptic non-touch technique (ANTT). That’s because it was actually pioneered in nursing, where many aseptic techniques “evolved more from anecdotal evidence and ritualistic practice than from empirical research,” according to an article published in the [...]

Parenteral Contract Manufacturers Design Efficient Processes to Ensure Compliant Products

The time, equipment, training, and cost required to create compliant parenteral products make outsourcing to parenteral contract manufacturers an attractive option for pharmaceutical companies. Because parenteral drugs bypass the body’s natural defenses, they must be totally sterile upon delivery, which means they must be sterilized completely during manufacture or processed [...]

Necessary Considerations for Viral Vector Development and Manufacturing

Viral vectors are at the cutting edge of gene therapy, cancer treatment, and vaccine development, but which vector is right for which therapy depends on a great number of factors. Advancements in the last few decades have led to much wider use of viral vectors in gene therapy, vaccines, and [...]

Syringe Filling at Scale to Deliver on the Increased Demand for Parenteral Product in Pre-Filled Syringes

Right now, pre-filled syringes are one of the most popular forms of delivery for countless parenteral products, both under hospital conditions and at home. What’s more, their popularity has grown exponentially in recent years, and shows no sign of slowing in the coming decades. However, the ubiquity of parenteral products [...]

Aseptic Processing of Sterile Drug Products—Current Industry Best Practices

Aseptic processing is used in many industries, for many purposes besides the production of sterile drug product. For example, aseptic processing has become the industry standard for handling liquid food products such as milk, fruit juice, and others—not to mention growing in popularity for foods like cottage cheese, vegetable soups, [...]